While I was in Japan (more of that in a future blog post), the electrical supply was connected for the CNC so it was ready for action on my return. I've been limited for time to get into the workshop but managed to grab a couple of hours today to cut some quick tests.

To begin with we levelled the machine using its adjustable feet and then plugged it in and a re-orientated myself with the control which thankfully is very straight-forward to use. I set up some toolpaths in Aspire to cut some simple circles, squares and text and ran those in some scrap MDF to make sure everything looked right. The vacuum table was excellent for holding down the material and tool setup was quick and easy.

Next I took a piece of oak and ran through the process of machining it flat with a surfacing bit. This is a good test of how level the machine is. Even though the oak had rough surfaces and was not perfectly flat, the vacuum still managed to hold it. The finish on the "planed" surface was excellent, so once one side was done I flipped it and flattened the other. Ordinarily with access to a planer I would not do this on the CNC but as previously mentioned its a good test for everything being in good shape.

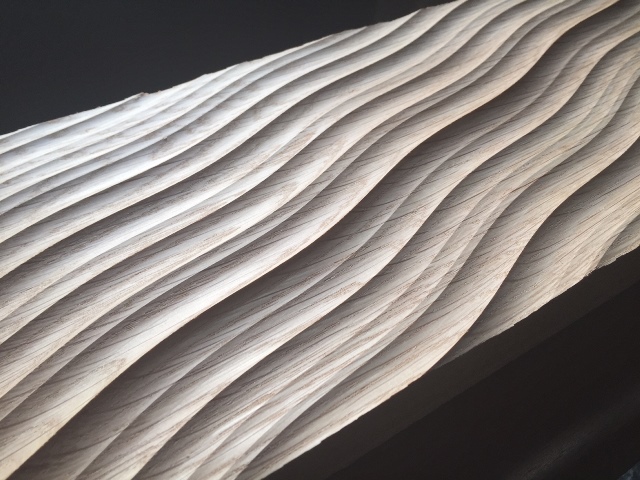

For the first proper cut carved the logo using a nice big 90 degree V-Bit, creating the V-Carving toolpath in Aspire. It cut really smoothly and again showed the machine is nice and level as the corners were sharp. Lastly I flipped the same piece of material over again and cut a wave texture using a 1" diameter ball-nose, really just to see how the tool worked. The cut was impressively smooth particularly given the amount of material it was removing on each pass.

All in all I was very happy with the machine on its first outing, the quality of cuts and ease of use of the control. Looking forward to when I can free up a bit more time to get back in the workshop!

CeorfanWorks logo carved into oak.

Wave texture cut in a single pass with 1" ballnose tool.